Product Overview

High-Strength Drywall Screws with Phosphate Coating

Our high-strength screws, made from durable 1022 steel, are designed specifically for attaching gypsum wallboard to wood or metal studs. The black phosphate coating offers excellent corrosion resistance, making them suitable for interior construction and renovation projects.

Bugle Head & Fine Thread Design

Each screw features a bugle head to reduce surface damage and a fine thread for secure fastening in drywall materials. These self-tapping drywall screws are available in four common lengths to suit various installation needs.

Bulk Supply for Global Construction Projects

We provide bulk packaging and global shipping, with a low MOQ of 15kg. Whether you’re working on residential ceilings or commercial drywall partitioning, our screws ensure reliable performance and easy installation.

Technical Specifications

| Certification Standard | JIS B1125 |

| Material | 1022 Carbon Steel (Tensile Strength ≥500MPa) |

| Surface Treatment | Black Phosphate (Film Weight ≥3μm) |

| Strength Grade | Grade A (Equivalent to Grade 4.8) |

| Head Type | Bugle Head |

| Thread Design | Double Lead Fine Thread |

| Corrosion Resistance | 48-hour Salt Spray Test |

| Suitable Materials | Gypsum Board (9-15mm), Light Steel Studs (≤0.6mm) |

| Available Sizes | M3.5×20, M3.5×25, M3.5×30, M3.5×35, M3.5×40, M3.5×50, M3.5×60, M3.5×70 (M3.5 Drywall Screws in Sizes: 3/4″, 1″, 1-3/16″, 1-3/8″, 1-5/8″, 2″, 2-3/8″, and 2-3/4″) |

Application Scenarios

Perfect for installing gypsum boards, lightweight partitions, and ceiling suspended ceilings. Suitable for securing to wooden or metal studs, as well as attaching door/window frames, skirting boards, cabinets, and other fittings to gypsum boards. Ideal for commercial construction and residential renovation projects:

Gypsum Board Installation

Ideal for mounting drywall to light steel or timber studs in residential and commercial construction

Ceiling and Partition Systems

Secure fit for interior wall systems and ceiling boards in modern building projects

Plywood and Fiberboard Fixing

Works well in lightweight board applications for interior finishing and renovation projects

Cabinet and Furniture Frames

Ensures reliable joints in softwood or engineered wood structures for furniture manufacturing

Home and Office Renovation

Common in fast interior finishing projects requiring professional appearance and durability

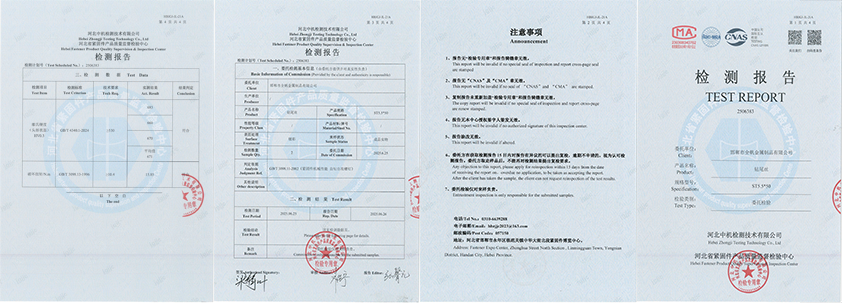

Product Quality Certificate

Quality Certification Standards

Product quality is our priority, validated by Hebei Provincial Fastener Product Quality Supervision and Inspection Center. This authoritative provincial institution has rigorously tested our screws, nuts and bolts for material, hardness, strength, precision and corrosion resistance—all meeting or exceeding industry standards. This certification guarantees reliable performance for your projects.

Product Packaging Specifications

Comprehensive Packaging Solutions

- Inner Packaging: 25kg per woven bag or small box, PE bag lining

- Outer Packaging: 900kg wooden pallets or fumigated plywood cases

- Custom Packaging: Logo boxes, barcode stickers available on request

Manufacturing Facility Overview

Advanced Manufacturing Facility

Our 5,000㎡ workshop features clear zones for raw materials, processing, testing and finished goods. Equipped with over 50 advanced CNC machines and cold headers, we achieve ±0.01mm precision from wire to finished fasteners. 20+ skilled staff monitor production, while a dedicated lab with tensile testers and spectrometers ensures strict quality checks—rejecting all substandard products.

Customer Service Policy

Return & Exchange Policy

We stand behind our high-quality fasteners. For defective products, returns are accepted within 7 days of receipt (unused, in original packaging, with defect evidence); we refund product cost (shipping non-refundable). Exchanges for wrong specs or minor defects (unused) are allowed within 7 days, with customer covering shipping. Not accepted: customer-caused errors, used/damaged products, requests after 7 days.

Frequently Asked Questions

Why is phosphated coating preferred for drywall screws?

Black phosphated coating offers excellent rust resistance and smooth driving performance without slipping. The coating also provides a professional black finish that blends well with interior applications and reduces visibility of fasteners.

Can these screws be used for metal studs?

Yes, they are specifically designed for fixing drywall to thin metal studs up to 0.8mm thickness. The sharp point and dual-thread design ensure reliable penetration and holding power in light steel framing systems common in Southeast Asia.

What are the differences between drywall screws sizes 3/4″, 1″, 1-3/16″, 1-3/8″, 1-5/8″, 2″, 2-3/8″, and 2-3/4″?

Drywall screws sizes vary to suit different panel thicknesses and project requirements:

• 3/4″ to 1″ screws are ideal for single drywall layers on wood studs, commonly used in Vietnam and Indonesia.

• 1-3/8″ to 1-5/8″ sizes are standard for 1/2″ or 5/8″ gypsum board, widely used in Egypt, Saudi Arabia, and Kenya.

• 2″ to 2-3/4″ drywall screws are chosen for double-layer drywall or insulation-backed installations, suitable for hot, humid environments like the UAE.

Choosing the right drywall screws size ensures firm fastening and long-lasting performance across various construction needs.

Are these screws magnetized for use with electric drivers?

Yes, they are compatible with magnetic bits, making power tool installation quick and efficient. The bugle head design works perfectly with standard drywall driver bits for professional installation results.

What’s the advantage of the bugle head design?

The bugle head design allows the screw to sit flush with or slightly below the drywall surface without tearing the paper face. This creates a smooth finish that’s ideal for painting and provides professional-quality results in interior applications.

Contact Us

Need more information about our High-Strength Black Phosphated Drywall Screws or have special requirements? Our technical sales team is ready to serve customers across Southeast Asia.

Get Quote Now