Product Overview

Countersunk head self-drilling screws with wings integrate “self-drilling, winged, and countersunk head” features to directly tackle key metal joining challenges: cumbersome pre-processing, thin material damage, and surface unevenness. They are ideal for industries requiring mass production, thin metal processing, and high surface precision—including manufacturing, construction, and home appliances. Supplied directly by Chinese factories, Quanfan offers you high-quality and cost-effective products.

Technical Specifications

| Product Standard | Enterprise Standard (customizable to DIN or ANSI requirements) |

| Material | Q235 Carbon Steel |

| Surface Treatment | Blue-White Zinc Electroplating (Thickness 5-8μm) |

| Strength Grade | Grade A (Equivalent to Grade 4.8) |

| Head Type | Cross recessed countersunk head (compatible with PH2 bits) |

| Drill Tip | Integrated self-drilling point with winged shank (clip-ear type) |

| Corrosion Resistance | 72-hour Neutral Salt Spray Test |

| Recommended Sheet Thickness | Suitable for metal sheets from 0.5 to 1.5 mm |

| Wing Span (Clip-Ear Diameter) | 1.2–1.5× the diameter of the screw shaft |

| Available Sizes | 4.2×25 mm (1″), 4.2×32 mm (1‑1/4″), 4.2×38 mm (1‑1/2″), 4.2×50 mm (2″) |

Application Scenarios

These Cross Head Countersunk Self-Drilling Screws with Wings is specifically designed for metal material connections, with typical application scenarios including:

Metal sheet assembly

Such as the splicing of steel structure frames, metal shelves, distribution box enclosures, and elevator car metal panels.

Home appliance/automotive manufacturing

Fixing metal casings of refrigerators and washing machines, and connecting automotive body panels and chassis metal components.

Outdoor metal facilities

Securing metal parts of guardrails, billboard frames, and photovoltaic brackets.

Furniture and Fixtures

Commonly used in factory-made furniture frames, storage racks, and metal cabinets. The flush countersunk head improves both safety and appearance.

Thin metal processing

Connecting relatively thin metal materials (usually 0.5-6mm thick) such as galvanized sheets, aluminum sheets, and cold-rolled steel sheets.

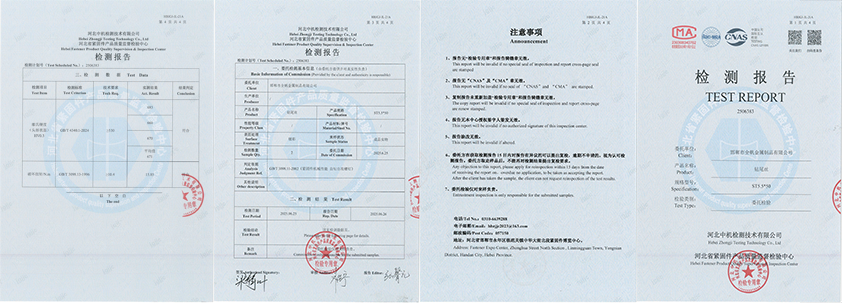

Product Quality Certificate

Quality Certification Standards

Product quality is our priority, validated by Hebei Provincial Fastener Product Quality Supervision and Inspection Center. This authoritative provincial institution has rigorously tested our screws, nuts and bolts for material, hardness, strength, precision and corrosion resistance—all meeting or exceeding industry standards. This certification guarantees reliable performance for your projects.

Product Packaging Specifications

Comprehensive Packaging Solutions

- Inner Packaging: 25kg per woven bag or small box, PE bag lining

- Outer Packaging: 900kg wooden pallets or fumigated plywood cases

- Custom Packaging: Logo boxes, barcode stickers available on request

Manufacturing Facility Overview

Advanced Manufacturing Facility

Our 5,000㎡ workshop features clear zones for raw materials, processing, testing and finished goods. Equipped with over 50 advanced CNC machines and cold headers, we achieve ±0.01mm precision from wire to finished fasteners. 20+ skilled staff monitor production, while a dedicated lab with tensile testers and spectrometers ensures strict quality checks—rejecting all substandard products.

Customer Service Policy

Return & Exchange Policy

We stand behind our high-quality fasteners. For defective products, returns are accepted within 7 days of receipt (unused, in original packaging, with defect evidence); we refund product cost (shipping non-refundable). Exchanges for wrong specs or minor defects (unused) are allowed within 7 days, with customer covering shipping. Not accepted: customer-caused errors, used/damaged products, requests after 7 days.

Frequently Asked Questions

Are the screws compatible with PH2 drivers?

Yes. These cross recessed countersunk screws are designed for use with standard PH2 screwdrivers or bits, making them easy to install with most manual or electric tools commonly used on job sites..

What problems do self-drilling screws with wings solve?

Self-drilling screws with wings solve key issues through their design: their self-drilling tip skips pre-drilling/threading, cutting installation time; wings pre-cut material and reduce pressure, preventing thin sheets (steel, aluminum) from warping or cracking; when paired with countersunk heads, they sit flush, avoiding surface protrusions for a smooth finish; and tight thread engagement ensures secure, vibration-resistant connections in steel, wood, etc.

Can these winged self-drilling screws be used for wood-to-metal connections?

es. The clip-ear (winged) design is specifically made for wood-to-metal applications. The wings enlarge the hole in wood, allowing the drill tip to smoothly penetrate the underlying steel without damaging the threads—ideal for roofing, framing, and panel installations.

Can I request specific sizes or custom packaging?

Yes, we support custom sizes and packaging with your logo or design based on minimum order quantities. Our flexible manufacturing capabilities serve diverse market needs across Southeast Asia.

What surface treatment is used for corrosion protection?

The screws are finished with a blue-white zinc plating (5–8 μm thickness), providing strong corrosion resistance. They pass a 72-hour neutral salt spray test, making them suitable for humid regions in Southeast Asia, the Middle East, and coastal Africa.

Contact Us

Need more information about our Cross Countersunk Head Clip-Ear Drill Tail Screws or have special requirements? Our technical sales team is ready to serve customers across Southeast Asia.

Get Quote Now