Product Overview

This carbon steel zinc plated Spring Washers (GB/T 1972-A-1-2005) is designed to prevent bolts and nuts from loosening due to vibration in machinery, automotive, and construction applications. Manufactured by a professional Chinese supplier, it features high-strength SAE 1074 carbon steel with 8-12μm zinc plating for durability. Available in standard sizes from 1/4″ to 1-1/8″, this spring washer maintains tension under vibration and thermal expansion, ensuring secure fastening in industrial equipment, electrical installations, and structural assemblies. The product offers precise dimensions (±0.1mm) and withstands temperatures from -30°C to 120°C, making it ideal for demanding environments. Bulk quantities and custom specifications available.

Technical Specifications

| Material | Carbon Steel |

| Surface Treatment | Zinc Plating |

| Standard Compliance | GB/T 1972-A-1-2005 |

| Tolerances | Inner/Outer Diameter: ±0.1mm, Thickness: ±0.05mm |

| Working Load | 500N (1/4″) to 10,000N (1-1/8″) |

| Fatigue Life | ≥50,000 cycles at 80% working load |

| Operating Temperature | -30°C to +120°C |

| Salt Spray Resistance | ≥96 hours (ISO 9227) |

| Available Sizes | 1/4″, 5/16″, 3/8″, 7/16″, 1/2″, 5/8″, 3/4″, 7/8″, 1″, 1-1/8″ |

Zinc Plated Carbon Steel Spring Washers Size Chart (GB/T 1972-A-1-2005)

| Inch Size | Metric Equivalent | Inner Diameter (ID) | Outer Diameter (OD) | Thickness (T) | Free Height (H) | Zinc Coating |

|---|---|---|---|---|---|---|

| 1/4″ | 6.35 mm | 6.5±0.1 mm | 12.0±0.1 mm | 1.2 mm | 2.5 mm | 8-12μm |

| 5/16″ | 7.94 mm | 8.0±0.1 mm | 15.0±0.1 mm | 1.5 mm | 3.0 mm | 8-12μm |

| 3/8″ | 9.53 mm | 10.0±0.1 mm | 18.0±0.1 mm | 1.8 mm | 3.6 mm | 8-12μm |

| 7/16″ | 11.11 mm | 11.5±0.1 mm | 21.0±0.1 mm | 2.0 mm | 4.0 mm | 8-12μm |

| 1/2″ | 12.70 mm | 13.0±0.1 mm | 24.0±0.1 mm | 2.2 mm | 4.4 mm | 8-12μm |

| 5/8″ | 15.88 mm | 16.0±0.1 mm | 30.0±0.1 mm | 2.5 mm | 5.0 mm | 8-12μm |

| 3/4″ | 19.05 mm | 19.0±0.1 mm | 36.0±0.1 mm | 3.0 mm | 6.0 mm | 8-12μm |

| 7/8″ | 22.23 mm | 22.5±0.1 mm | 42.0±0.1 mm | 3.5 mm | 7.0 mm | 8-12μm |

| 1″ | 25.40 mm | 25.0±0.1 mm | 48.0±0.1 mm | 4.0 mm | 8.0 mm | 8-12μm |

| 1-1/8″ | 28.58 mm | 28.5±0.1 mm | 54.0±0.1 mm | 4.5 mm | 9.0 mm | 8-12μm |

Application Scenarios

These carbon steel zinc-plated spring washers (GB/T 1972-A-1-2005) are widely used in industries requiring vibration resistance, anti-loosening, and corrosion protection. Below are key application scenarios:

Automotive Assembly

Prevents bolt loosening in engines, transmissions, and suspension systems under constant vibration. Ideal for securing critical components like exhaust manifolds and wheel hubs.

Industrial Machinery

Maintains fastener tension in pumps, compressors, and conveyor systems, reducing maintenance downtime caused by vibration-induced failures.

Construction & Steel Structures

Provides reliable anti-loosening for bridges, prefabricated buildings, and HVAC installations, resisting wind and dynamic loads.

Electrical & Electronics

Secures terminal blocks, control panels, and appliance wiring, preventing loose connections in high-vibration environments.

Renewable Energy Systems

Ensures long-term stability for solar panel mounts and wind turbine bolts, enduring thermal cycling and weather exposure.

Agricultural Equipment

Withstands shocks and vibrations in tractors, harvesters, and irrigation systems, reducing fastener fatigue in harsh field conditions.

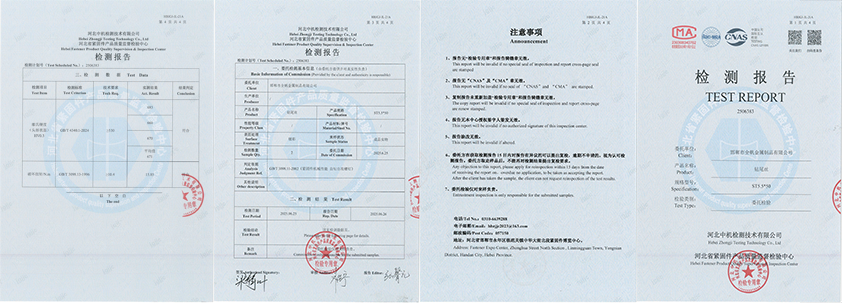

Product Quality Certificate

Quality Certification Standards

Product quality is our priority, validated by Hebei Provincial Fastener Product Quality Supervision and Inspection Center. This authoritative provincial institution has rigorously tested our screws, nuts and bolts for material, hardness, strength, precision and corrosion resistance—all meeting or exceeding industry standards. This certification guarantees reliable performance for your projects.

Product Packaging Specifications

Comprehensive Packaging Solutions

- Inner Packaging: 25kg per woven bag or small box, PE bag lining

- Outer Packaging: 900kg wooden pallets or fumigated plywood cases

- Custom Packaging: Logo boxes, barcode stickers available on request

Manufacturing Facility Overview

Advanced Manufacturing Facility

Our 5,000㎡ workshop features clear zones for raw materials, processing, testing and finished goods. Equipped with over 50 advanced CNC machines and cold headers, we achieve ±0.01mm precision from wire to finished fasteners. 20+ skilled staff monitor production, while a dedicated lab with tensile testers and spectrometers ensures strict quality checks—rejecting all substandard products.

Customer Service Policy

Return & Exchange Policy

We stand behind our high-quality fasteners. For defective products, returns are accepted within 7 days of receipt (unused, in original packaging, with defect evidence); we refund product cost (shipping non-refundable). Exchanges for wrong specs or minor defects (unused) are allowed within 7 days, with customer covering shipping. Not accepted: customer-caused errors, used/damaged products, requests after 7 days.

Frequently Asked Questions

What standards do your spring washers comply with?

Our carbon steel spring washers meet GB/T 1972-A-1-2005 (Chinese national standard) and are compatible with ANSI B18.21.1 specifications. Zinc plating follows ASTM B633 for corrosion resistance.

What sizes are available? Can you supply non-standard sizes?

Standard sizes: 1/4″ to 1-1/8″ (see size chart for metrics). Custom sizes are available (MOQ applies)—provide drawings or specs for quotation.

Can you match other standards (DIN, JIS)?

Yes—we produce washers to DIN 127 (Germany) or JIS B 1251 (Japan) standards. Provide details for confirmation.

What is the fatigue life of these spring washers?

Our spring washers provide ≥50,000 cycles at 80% working load, ensuring long-term reliability in high-vibration applications.

How do these spring washers prevent loosening?

The spring washer maintains constant tension between the bolt head/nut and the workpiece, compensating for vibration and thermal expansion to prevent fastener loosening.

What temperature range can these washers withstand?

Our zinc-plated spring washers operate reliably from -30°C to +120°C, making them suitable for most industrial and automotive applications.

Contact Us

Need more information about our Spring Washers or have special requirements? Our technical sales team is ready to serve customers worldwide with customized solutions.

Get Quote Now